High Purity WA Micro Grits (Low Sodium)

With strong chemical stability and high insulativity, it is applied to consolidation and coated abrasives, wet or dry blasting sand, precision grinding for industry of crystal or electronics, and making high level refractory materials.

Product Details

With strong chemical stability and high insulativity, it is applied to consolidation and coated abrasives, wet or dry blasting sand, precision grinding for industry of crystal or electronics, and making high level refractory materials. And it is also suitable for producing the higher hardness and tensile strength material, such as alloy steel, high speed steel and high carbon steel, ect. It also can be used to make contacting media material, insulator and precise casting sand. According to the purity,we can supply both Na2O 0.3% and Low soda Na2O 0.05% products.

Applications

a.) WFA Grinding wheel, cutting wheel, abrasive disc,

b.) Fine sandblasting(such as mobile phone cover,etc), polishing

c.) Abrasive paper, abrasive belt

| Item | Al2O3 % | Fe2O3 % max | SiO2 % max | Na2O % max |

| TW-Ⅰ | 99.5 | 0.05 | 0.10 | 0.35 |

| TW-Ⅱ | 99.7 | 0.05 | 0.10 | 0.06 |

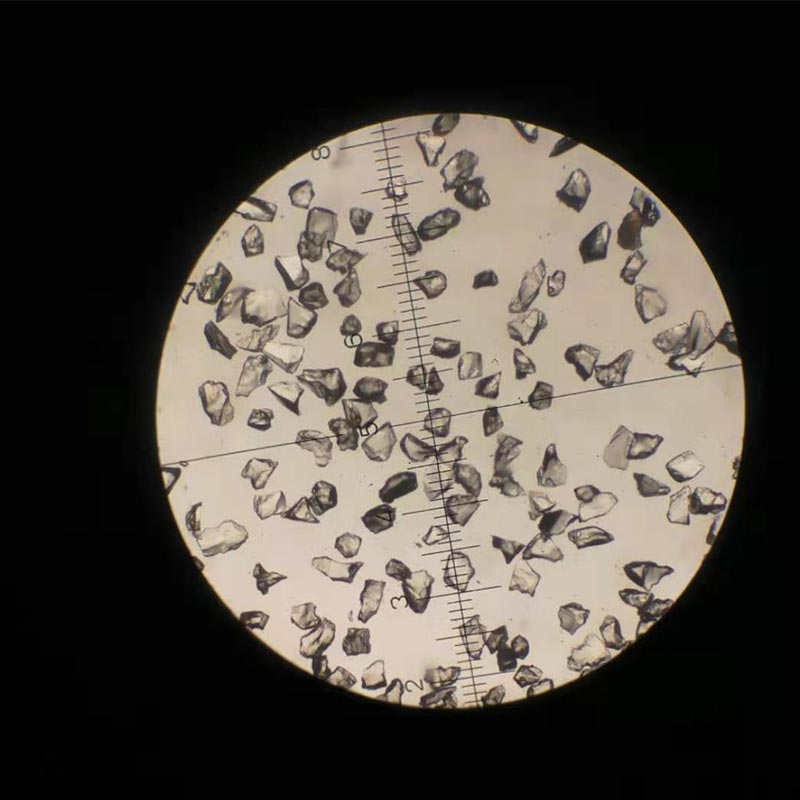

Fused Alumina Abrasives Micro Grits Size

| FEPA SIZE | Average grain size (μm) | ||

| ds3 (μm) max | ds50 (μm) | ds94 (μm) min | |

| F 230 | 77 | 55.7 ± 3.0 | 38 |

| F 240 | 68 | 47.5 ± 2.0 | 32 |

| F 280 | 60 | 39.9 ± 1.5 | 25 |

| F 320 | 52 | 32.8 ± 1.5 | 19 |

| F 360 | 46 | 26.7 ± 1.5 | 14 |

| F 400 | 39 | 21.4 ± 1.0 | 10 |

| F 500 | 34 | 17.1 ± 1.0 | 7 |

| F 600 | 30 | 13.7 ± 1.0 | 4.6 |

| F 800 | 26 | 11.0 ± 1.0 | 3.5 |

| F 1000 | 23 | 9.1 ± 0.8 | 2.4 |

| F 1200 | 20 | 7.6 ± 0.5 | 2.4 |

| FEPA abrasives micro size distribution | |||

| Settlement pipe particle size analysis | |||

| ds3 | ds50 | ds94 | |

| F230 | 77 | 55.7±3.0 | 38 |

| F240 | 68 | 47.5±2.0 | 32 |

| F280 | 60 | 39.9±1.5 | 25 |

| F320 | 52 | 32.8±1.5 | 19 |

| F360 | 46 | 26.7±1.5 | 14 |

| F400 | 39 | 21.4±1.0 | 10 |

| F500 | 34 | 17.1±1.0 | 7 |

| F600 | 30 | 13.7±1.0 | 4.6 |

| F800 | 26 | 11.0±1.0 | 3.5 |

| F1000 | 23 | 9.1±0.8 | 2.4 |

| F1200 | 20 | 7.6±0.5 | 2.4 |

| Abrasives micro size distribution Japan standard JIS#240~10000 | ||||||||

| Settlement pipe particle size analysis method(μm) | Electric-resistivity grain counter method(μm) | |||||||

| ds0 | ds3 | ds50 | ds94 | ds0 | ds3 | ds50 | ds94 | |

| #240 | 127 | 90 | 60±4.0 | 48 | 127 | 103 | 57±3.0 | 40 |

| #280 | 112 | 79 | 52±3.0 | 41 | 112 | 87 | 48±3.0 | 33 |

| #320 | 98 | 71 | 46±2.5 | 35 | 98 | 74 | 40±2.5 | 27 |

| #360 | 86 | 64 | 40±2.0 | 30 | 86 | 68 | 35±2.0 | 23 |

| #400 | 75 | 56 | 34±2.0 | 25 | 75 | 58 | 30±2.0 | 20 |

| #500 | 65 | 48 | 28±2.0 | 20 | 63 | 50 | 25±2 | 16 |

| #600 | 57 | 43 | 24.0±1.5 | 17 | 52 | 41 | 20±1.5 | 13 |

| #700 | 50 | 39 | 21.0±1.3 | 14 | 45 | 37 | 17±1.3 | 11 |

| #800 | 46 | 35 | 18.0±1.0 | 12 | 38 | 31 | 14±1.0 | 9 |

| #1000 | 42 | 32 | 15.5±1.0 | 9.5 | 32 | 27 | 11.5±1.0 | 7 |

| #1200 | 39 | 28 | 13.0±1.0 | 7.8 | 27 | 23 | 9.5±0.8 | 5.5 |

| #1500 | 36 | 24 | 10.5±1.0 | 6.0 | 23 | 20 | 8.0±0.6 | 4.5 |

| #2000 | 33 | 21 | 8.5±0.7 | 4.7 | 19 | 17 | 6.7±0.6 | 4 |

| #2500 | 30 | 18 | 7.0±0.7 | 3.6 | 16 | 14 | 5.5±0.5 | 3 |

| #3000 | 28 | 16 | 5.7±0.5 | 2.8 | 13 | 11 | 4.0±0.5 | 2 |

| #4000 | 4.7±0.4 | 11 | 8 | 3.0±0.4 | 1.3 | |||

| #6000 | 8 | 5 | 2.0±0.4 | 0.8 | ||||

| #8000 | 6 | 3.5 | 1.2±0.3 | 0.6(ds75) | ||||

| #10000 | 0.8±0.2 | |||||||

Packing

1000kg or 1250kg bulk bags

Bulk bag on pallets

25kg woven bag in bulk bags

25kg paper bag on pallets

Related Products

Inquiry

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.

EN

EN ES

ES JA

JA RU

RU